Summary

- Honda is renowned for its ironclad reliability and ease of maintenance, with engines and transmissions lasting over 200,000 miles with regular maintenance.

- Honda’s manufacturing methodology seamlessly blends robotic precision with human scrutiny, resulting in vehicles that embody unwavering reliability and uniformity.

- Japanese manufacturing methodologies, emphasizing waste reduction and efficiency, contribute to Honda’s commitment to crafting dependable and economical family vehicles. Motorsports have also played a crucial role in Honda’s innovation and engine-building expertise.

When you think about cars and reliability, Honda is definitely the first or second name that comes to mind. The Japanese manufacturer is renowned for their ironclad reliability and ease of maintenance. Honda engines and transmissions regularly last upwards of 200,000 miles with only regular maintenance. Honda also stands prominently within the realm of resale, along with Toyota. Across the board, Honda models like Civic, Accord, CR-V, and Pilot which are household names; always perform, securing the fourth spot in five-year resale value with an impressive 77.7 percent average. Among the models boasting exceptional resale value after five years, the Honda Civic claims a notable third place.

There are numerous factors contributing to Honda’s exceptional dependability. One plausible reason could be their cost-effective repair and maintenance costs. Honda vehicles experience minimal downtime, due to their hassle-free maintenance, resulting in enhanced reliability. This approach stands in stark contrast to the challenges faced by luxury brands, often burdened by the high costs and prolonged durations associated with sourcing and replacing parts, leading to reduced dependability. In contrast, Honda owners face fewer repair issues in the long run, hence bolstering the brand’s reputation for heightened reliability.

Synergy And Precision: Honda’s Blend Of Robotic Efficiency And Human Insight In Manufacturing

Within every Honda assembly station, the workmanship extends beyond robotic machinery controlling welding and bolting operations. Techniques like JIT and Kaizen are part of Honda’s manufacturing methodology seamlessly, that intertwines the precision of robotics with the nuanced scrutiny of humans while upholding the most stringent industry benchmarks.

The process is impeccably calibrated on the assembly line over decades to identify and rectify errors seamlessly. Notably, the methodologies employed not just in Honda, but the entire Japanese automobile assemblies have garnered admiration across the globe. Through the engagement of individuals at each phase of manufacturing and development, Honda vehicles are meticulously crafted to embody unwavering reliability and uniformity.

The advent of increased automation has reshaped the roles of humans, while streamlining inventory management. The resultant outcome is harmony and cost-effectiveness with elevated quality and value, setting unparalleled standards for the competition.

However, it’s the meticulous attention to detail that truly exemplifies the superiority of Honda cars. In instances where manual labor prevails, a sense of thoughtfulness, comfort, and meticulousness imbues each vehicle. In the modern landscape, Honda assemblies embody a harmonious blend of robotic precision and the human touch.

Honda’s Reliability Ethos Draws Inspiration From Its Historical Journey

Honda is primarily an engine builder. Along with other Japanese manufacturers, enjoyed remarkable success during the 1980s, which made numerous Western researchers and academics take notice of Japanese managerial philosophies.

Following an in-depth study of Japanese automobile production, it was concluded by many that the competitive edge of Japanese companies didn’t solely stem from technological supremacy. While deploying akin technologies and technical processes, Japanese counterparts consistently outperformed their counterparts in terms of productivity.

In the 20th Century, Japanese manufacturing methodologies took shape, emphasizing the reduction of waste, heightened efficiency, and an unwavering dedication to eradicating technical flaws, even if it meant sacrificing sheer output. This approach, often referred to as “lean manufacturing,” prioritizes optimized processes.

Rather than pursuing unproven advancements, they embrace a meticulous approach, ensuring reliability and performance before incorporation. Notably, a significant proportion of Japanese manufacturers channel their efforts into crafting dependable and economical family vehicles, veering away from a strong emphasis on high-performance cars. This strategic focus underscores their commitment to meeting the needs of a broad spectrum of consumers.

The intricate interplay between Japanese corporate and societal culture also contributes significantly to their manufacturing philosophy. This unique cultural backdrop fosters an environment where precision, attention to detail, and a commitment to continuous improvement thrive, resulting in the exceptional standards for which Japanese products are renowned.

Motorsports: The Crucible Of Automotive Innovation For Road Cars

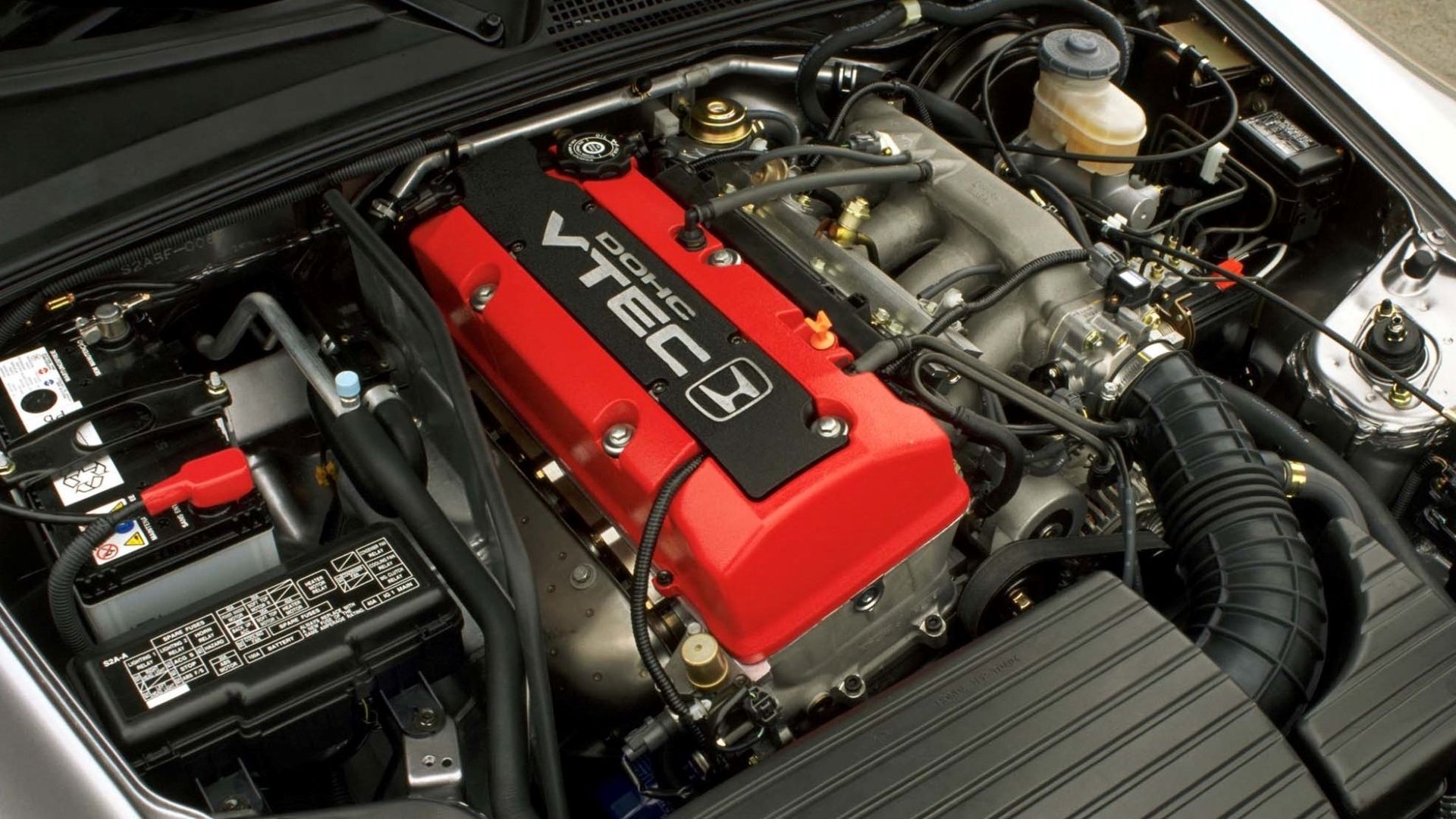

Throughout its history, the automotive industry has consistently depended on motorsports as a testing ground for innovations destined for use in production vehicles. Merely one year after its establishment as a car manufacturer in 1963, Honda embarked on a bold journey into racing.

Further, demonstrating remarkable fearlessness, the company decided to venture into designing its own chassis and engine firstly, with the RA271 F1 car and later, the RA272 F1 car. This decision quickly bore fruit two years later, as in the year 1965, at the Mexican Grand Prix, F1 Legend Richie Ginther steered Honda to its inaugural victory on the track. This was the first time a Japanese car won the event.

In the year 1988, Honda achieved an unprecedented feat in the realm of Formula 1. A level of dominance unmatched before or since was demonstrated as the McLaren-Honda collaboration emerged triumphant in 15 out of 16 races during the season.

This remarkable performance led to the team securing the Constructors’ Championship title. Ayrton Senna solidified his position as the 1988 Formula 1 World Champion, with his teammate Alain Prost securing the runner-up position. The result of years of excellence and engine-building expertise was Honda got to perfect their engine technology and build the rock-solid performance engines we know and love today.

The Hallmarks Of Honda’s Philosophy: Values, Principles, And Commitments

Central to Honda’s philosophy is a profound Respect for the Individual. This core belief underscores their conviction in the intrinsic worth of every person, advocating for their treatment with honor and consideration. Additionally, the company is also guided by “The Three Joys,”- The Joy of Buying, The Joy of Selling, and the Joy of Creating.

Firstly, the joy of buying stems from surpassing customer needs and expectations through products and services. Secondly, the joy of selling arises from nurturing trust-based relationships between sales and service teams and customers, fostering satisfaction and pride in representing Honda. Lastly, the joy of creating resonates with Honda associates and suppliers, sparked by the recognition of customer and dealer delight through quality products, instilling pride in accomplished work.

Embracing Social Responsibility, Honda actively commits to forging a sustainable future. Balancing economic advancement with environmental guardianship, the company pledges to play a pivotal role in shaping a harmonious coexistence between growth and ecological well-being.

Dedicated to unwavering quality and safety, Honda stands resolved to furnish its customers with products and services of the utmost caliber and dependability. Stringently adhering to the highest safety and reliability benchmarks, Honda ensures the provision of superior quality and unwavering safety assurance.

Driving Excellence: Honda’s Enduring Legacy Of Values, Craftsmanship, And Innovation

Honda’s journey through the automotive landscape reflects a dedication to excellence that extends far beyond the confines of engineering and innovation. It’s a testament to the power of values, meticulous craftsmanship, and a commitment to serving both individuals and the environment.

Within Honda’s R&D centers and factories, associates don pristine white work uniforms, embodying the belief that “excellent products emerge from clean workspaces.” The color white encapsulates Honda’s philosophy of wholehearted dedication to crafting products, resonating not just within its Japanese facilities but globally. This distinctive white uniform also stands as a representation of equality among all Honda personnel, across all levels.

From the racetracks to the assembly lines, Honda’s legacy is one of pushing boundaries, embracing challenges, and embodying the spirit of joy in every endeavor. As the road ahead unfolds, Honda’s unwavering pursuit of quality, reliability, and innovation continues to guide its path, lighting the way for a future where excellence knows no bounds. With every milestone, Honda remains a beacon of inspiration, proving that a steadfast commitment to principles can shape industries and define eras.

Source

https://www.topspeed.com/why-are-hondas-so-reliable/